Full turnkey package solutions for all your switchgear and Busduct requirements.

Switchgear : Busducts

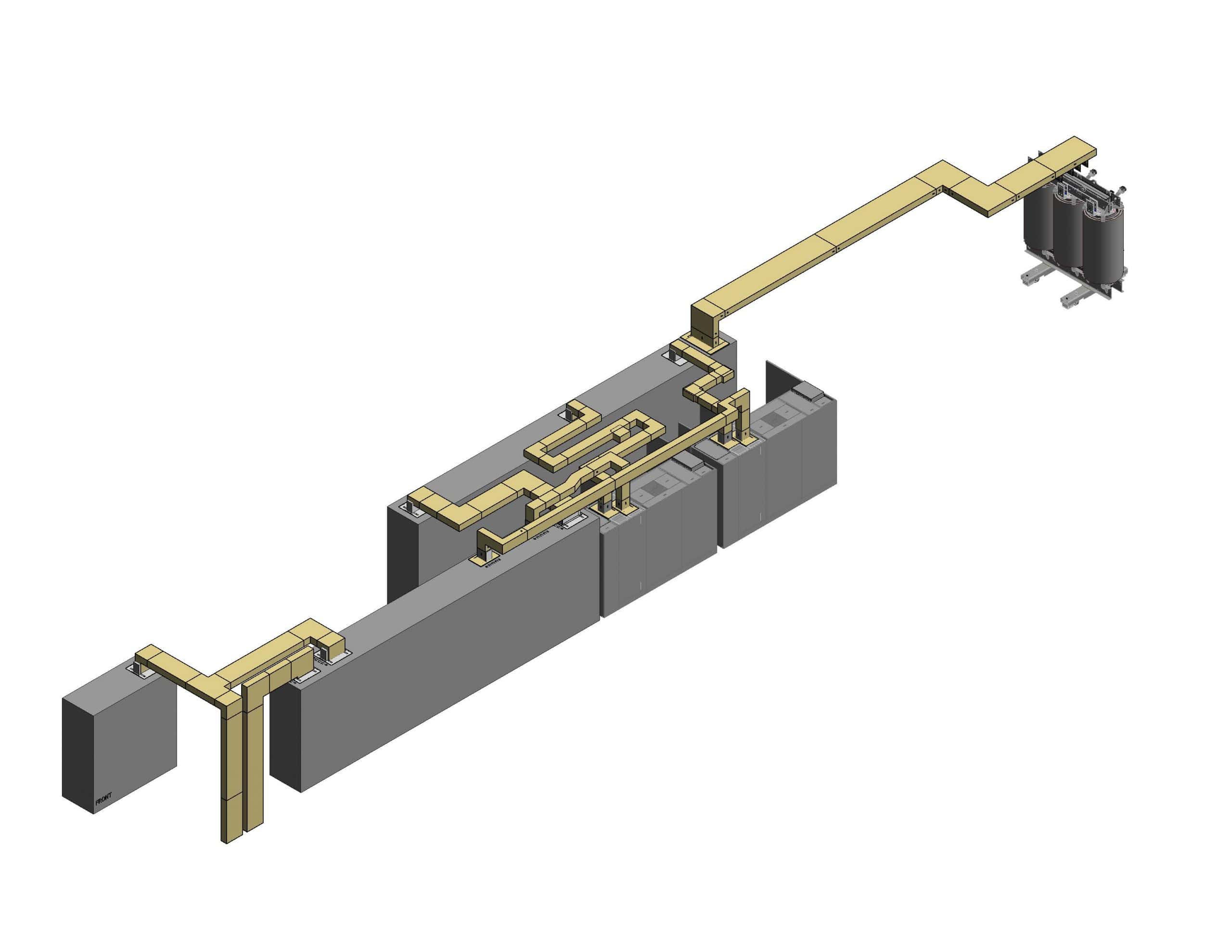

Busduct Systems

Using BIM modelling our team of Engineers can design the optimum busduct route, minimising on site measured parts to reduce the installation of the entire busduct system. Working with multiple busduct manufactures means that we can select the right system with the best lead times to ensure that your project is completed to the highest standards and on time.

Key features of TES’s Busduct System: