TES were recently awarded a project to supply power distribution equipment including UL rated LV Switchgear for a new state-of-the-art aluminium beverage can manufacturing facility. The new 355,000sqft, two-line facility, based in Nevada, has been designed to manufacture both standard and speciality beverage cans for a variety of categories, including carbonated soft drinks, sparkling water, energy drinks, hard seltzers, beer and ready-to-drink cocktails.

Contract specifications:

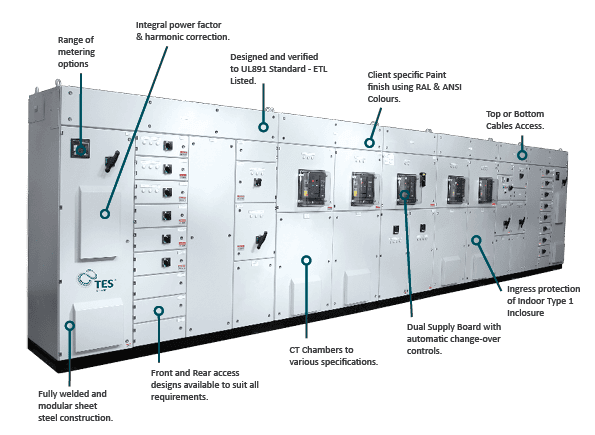

As part of the project TES supplied a total of 21 switchboards with the largest being over 16m long. In addition to the full switchboard package, we included several 504 KVAR Power Factor Correction boards consisting of 12no. 42KVAR steps.

Each Switchboard was built to the following specifications:

- Free standing, National Recognised Test Laboratory (NRTL) certified UL891, cubical type switchboard.

- Switchboard suitable for Rear cable access, Top cable entry, Top cable exit.

- Switchboard was constructed with BS EN 61439-2 Form 4b Type 2 and Type 6 style layout. With a Nema Type 1 indoor rating

- Tinned Bus Bars, rated at 3200A and have a short circuit withstand of 50kAIC

- Copper earth bar will run the length of the switchboard.

TES manufactures all switchgear from our 100,000 sqft TES Power Manufacturing facility in Ballykelly, Northern Ireland. With our significant increase in manufacturing space and new off-site manufacturing capabilities, TES was able to manufacture this project to UL891 Standards in a competitive and timely manner for our client and ship the finished switchgear package via sea freight to USA. On arrival, our TES team took to Nevada to install, test and commission the switchgear.