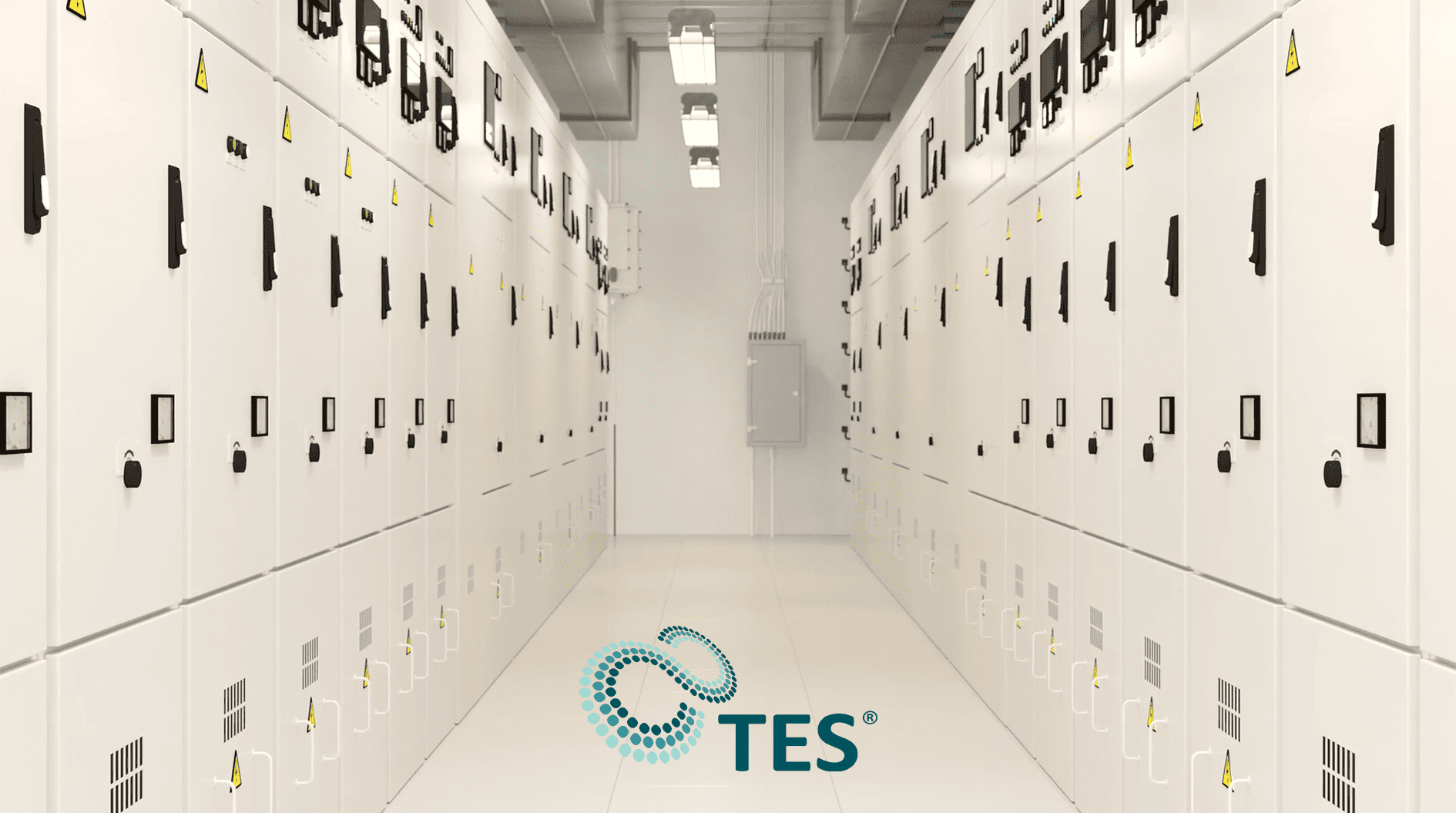

At TES, we manufacture and distribute switchboards in an efficient manner globally to our Data Centre clients. Here are some of the steps and factors that we follow to successfully execute this process.

Design and Planning

TES begins by designing the switchboard layout, taking into account the project’s specific customisation requirements, such as the number of circuits, load distribution, safety features, and compliance with relevant electrical codes and standards.

Standardisation

At TES we develop standardised designs and components that can be easily adapted for various projects. This reduces the need for custom solutions and simplifies the manufacturing process. However, we also have the facilities to customise and manufacture Switchgear to meet our Data Centre client’s specific project requirements.

The use of Advanced Technologies

TES has invested significantly in technologies that allow us to implement automated manufacturing where possible and speeds up the assembly process. Our skilled designers are efficient in computer-aided software such as Inventor, E-Plan and BIM 360.

In addition, TES use 3D printing for specific components and predictive analytics to optimise production efficiency and to identify areas for improvement.

Off-Site Manufacturing Solutions

TES accommodates Data Centre clients globally by utilising modular manufacturing techniques. All elements of our switchboards are prefabricated within our Data Centre Campus in Ballykelly and can be assembled off-site using our manufactured solutions, including skid-mounted and containerised products for rapid deployment. Therefore, accelerating the manufacturing process and reducing on-site work.

Skilled Workforce

TES are proud to have such a high calibre of skilled talent working within both Cookstown and our Ballykelly campus. Within our Data Centre Campus in Ballykelly, our workforce is proficient in the design and manufacturing of UL 891 Switchboards. Each element of the process is conducted on-site, fostering effective collaboration and communication between design, engineering, and manufacturing teams, thus preventing any delays.

Supply Chain Management

The TES Supply Chain Management team ensure that our factories have a steady and timely supply of components. We also adopt a universal agreement with suppliers, meaning we are not tied to one supplier’s components should they face disruptions, we multi-source. Therefore, reducing the chances of delays in delivery or production.

Furthermore, we apply lean manufacturing principles to eliminate waste, reduce unnecessary steps, and optimize the production flow.

Inspection, Testing & Quality Control

Inspection and Testing is a key element to TES’s overall Quality Control and Manufacturing process. Our skilled engineers ensure that each switchboard is thoroughly tested for functionality, safety and compliance before it leaves the factory. Therefore, detecting any early issues and delays.

Overall, TES has been able to advance and avoid issues that have been facing the switchboard manufacturing industry, such as capacity constraints, component shortages etc. We are proud to be an award-winning and reputable switchgear manufacturer within the Data Centre and Water/Wastewater industry.

However, it is important to note that whilst fast production within the switchboard manufacturing industry is beneficial, maintaining safety and quality standards is of the highest importance at TES. Our rapid manufacturing does not compromise the integrity or safety of our switchboards being produced.